Industry Fellowships

The Faraday Institution awarded its first Industry Fellowships in 2020, a programme to strengthen ties between battery researchers working in industry and academia.

Current Fellowships

Coventry University with FEV UK

Joe Fleming of Coventry University is collaborating with FEV Group to enhance cell monitoring of battery modules. The aim is to achieve efficient and reliable monitoring, control, and communication within battery modules, while minimising complexity and external wiring. The project is developing a novel approach that integrates multiple powerline communication sensor nodes directly within the battery modules at a cell-to-cell level. Powerline communication enables the simultaneous transmission of both data and power within the same conductor. The distributed battery management system developed will be cell and chemistry agnostic, making it suitable for all types of battery technology.

The University of Birmingham with the UK Battery Industrialisation Centre

An industry fellowship between UK Battery Industrialisation Centre (UKBIC) and the Energy Materials Group at the University of Birmingham will facilitate the sharing of knowledge on electrode slurry characterisation and modelling. It will improve the ability to predict the rheology of electrode slurries as they are scaled up from lab-scale to production scales, so reducing coating line dial-in times and scrap rates and improving product quality. The fellowship aims to further develop the understanding of how formulation impacts slurry and coating processability and provide rheological parameters as inputs to computational fluid dynamics models that can be used to predict slurry coat-ability and inform initial process parameters for production. The fellowship is led by Professor Emma Kendrick and Dr Carl Reynolds.

Read more about the fellowship.

The University of Sheffield with Finden

The successful collaboration between Prof Serena Cussen, University of Sheffield and Dr Stephen Price of Finden Ltd, which has been developing a characterisation technique that aims to inform strategies to mitigate deleterious behaviour in high nickel-content cathodes, has been extended with a follow-on Industry Fellowship. The first phase of the fellowship pushed X-ray diffraction computed tomography (XRD-CT) to the nanoscale, providing insights into the FutureCAT materials’ crystallite orientation and informing understanding of lithium diffusion pathways, mechanical strength and aging behaviour (of importance to designing materials capable of fast charging). The second phase aims to deliver standardised in-situ capabilities for the use of XRD-CT to determine how Ni-rich cathodes respond to different charge/discharge conditions. The new in-situ capabilities will be used to characterise pouch cells incorporating promising new materials developed by the FutureCAT project.

The successful collaboration between Prof Serena Cussen, University of Sheffield and Dr Stephen Price of Finden Ltd, which has been developing a characterisation technique that aims to inform strategies to mitigate deleterious behaviour in high nickel-content cathodes, has been extended with a follow-on Industry Fellowship. The first phase of the fellowship pushed X-ray diffraction computed tomography (XRD-CT) to the nanoscale, providing insights into the FutureCAT materials’ crystallite orientation and informing understanding of lithium diffusion pathways, mechanical strength and aging behaviour (of importance to designing materials capable of fast charging). The second phase aims to deliver standardised in-situ capabilities for the use of XRD-CT to determine how Ni-rich cathodes respond to different charge/discharge conditions. The new in-situ capabilities will be used to characterise pouch cells incorporating promising new materials developed by the FutureCAT project.

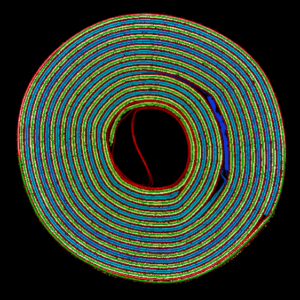

Image courtesy of Finden: Overlaid XRD-CT image of cell components identified in the AAA pristine battery cell: red – separator, yellow – anode (LiC12), green – copper current collector, cyan – cathode (primary NMC532), dark blue – aluminium current collector.

The University of Birmingham with Echion Technologies Ltd

Prof Peter Slater of the University of Birmingham is working with Echion Technologies to identify new mixed metal niobium oxide phases for possible use as anode materials, assess them for performance and thereafter take promising materials into Echion’s product development cycle with the aim of improving lithium-ion battery energy densities and charge times.

Read the success story about the collaboration.

Coventry University with Breathe Battery Technologies

Dr Tazdin Amietszajew of Coventry University’s Centre for Advanced Low Carbon Propulsion Systems (C-ALPS) is collaborating with Breathe Battery Technologies to advance battery management systems and cell behaviour tracking capabilities. Advanced real-life battery internal operating conditions will be tracked, with the aim of supporting the validation and development of new battery management and control approaches for electric cars. The project will focus on bespoke in-situ cell monitoring techniques, which will allow for deeper and clearer insights into a battery’s operating conditions. These insights will support Breathe Battery Technologies’ continued development of battery management software that is compatible with today’s embedded systems in cars and electronics, where only standard temperature, voltage and current sensors are available. These solutions will be applicable in the automotive industry and in other sectors where performance and safety are crucial.

Imperial College London with Hitachi High-Tech Europe

Dr Ann Huang from Imperial College London is partnering with Hitachi High-Tech Europe to develop, refine and commercialise innovative electrode manufacturing equipment. This will optimise ion diffusivity for both lithium-ion batteries (LIBs) and solid-state batteries (SSBs), with the potential for making a step increase in energy densities at fast charging for both LIBs and SSBs.

Imperial College London with Deregallera

Dr Nuria Tapia-Ruiz of Imperial College London is partnering with Deregallera to improve the processing of high-performance hard carbons for sodium-ion batteries. The project aims to use MgO templates to produce high-capacity hard carbons (>350 mAh/g). The team is working towards improving and optimising the templating process for industrial applications, through the use of mild acids, to regenerate MgO templates with the aim of eliminating hazardous HCl waste, providing renewable feedstocks and thus reducing disposal and bill-of-material costs.

Completed Fellowships

University of Strathclyde with CDO2

Dr Terry Dyer at the University of Strathclyde is working with CDO2 on the miniaturisation of quantum magnetometry sensors. By taking sensitive magnetometer readings, CDO2 can visualise and monitor the current flow within battery cells and packs, with obvious implications for development of both cell and pack designs without the complications of invasive sensing technologies. The fellowship is working towards a new sensor design that has the potential to have superior cost, size, accuracy and cost characteristics than existing technology and allow a significant number of sensors to be embedded in either prototype or serial application designs

Imperial College London with Ilika Technologies

Prof Greg Offer and Dr Ganesh Madabattula at Imperial College London are partnering with Ilika to utilise the modelling tools developed by the Multi-Scale Modelling project and begin to apply them to solid-state batteries. This modelling of the fundamental physics governing solid-state batteries is allowing Ilika to rapidly trial various modifications to both the chemistry and physical make up of their designs, without having to commit to the cost and time involved in producing and then testing a large number of physical prototypes. This project is initially focussed on the modelling of the high-capacity silicon anode material used by Ilika.

Cranfield University with Delta Cosworth

Cranfield University with Delta Cosworth

Dr Abbas Fotouhi at Cranfield University is working with Delta Cosworth to explore potential applications of artificial intelligence to develop novel temperature prediction techniques that improve the performance of battery thermal management systems, bringing possible benefits to battery performance and lifespan.

Read the success story about the collaboration.

University of Sheffield with TFP Hydrogen Products

Prof Serena Cussen and Dr Glen Murray of the University of Sheffield are working with TFP Hydrogen Products to develop processes to control particle morphology and size for next-generation high-nickel cathode materials in a continuous manufacturing process, as part of a long-term aim of maximising battery performance and reducing manufacturing costs.

University of Sussex with CDO2

Prof Peter Kruger and Dr Christopher Abel of the University of Sussex are working with CDO2 to characterise and understand the capability of a newly developed device based on quantum magnetometer technology that could potentially be used to improve the prediction of state-of-health and state-of-charge on-board electric vehicles.

Imperial College London with WAE

Dr Billy Wu of Imperial College London will lead a Fellowship with Williams Advanced Engineering (WAE) to accelerate the deployment of advanced physics-based modelling (developed as part of the Multi-scale Modelling Project) to improve the diagnostic and prognostic capability of the WAE battery management system, targeting an extension in battery life.

Read the success story about the collaboration.

The University of St Andrews with AMTE Power

Prof John Irvine, Dr Rob Armstrong and Dr Paul Connor of the University of St Andrews are working with AMTE Power to strengthen the pathway from laboratory to cell production. The partnership is focusing on taking newly developed sodium-ion materials from the laboratory to fully functioning pouch cells as an exemplar technology allowing the building of combined capability. The fellowship is strengthening the industry partner’s awareness and capability in battery research and enhancing the university partner’s capability to transition cells to full scale.

University of Sheffield with Exawatt

Dr Alisyn Nedoma and Dr Sam Booth from the University of Sheffield will work closely with the team at Exawatt (a key industry partner of the FutureCat project) to develop a techno-economic analysis and forecasting model of the cost of possible novel cathode materials given market raw materials costs and manufacturing methods. The tool will guide cathode research and scale-up options and has potential for use by automakers and to inform policy.

Coventry University with Nyobolt

Dr Alexander Roberts at Coventry University is working with Nyobolt to prototype their niobium-based anode materials into working battery cells. The collaboration is proving highly successful for both parties involved, with prototype cells confirming performance potential that supported a recent funding round for Nyobolt. Dr Roberts benefits from career development opportunities from interacting with the technical and commercial teams at Nyobolt as they head towards larger scale production. The success of the programme has led to a second Fellowship being awarded in 2021.

Dr Alastair Hales with Thermal Hazard Technology

Dr Alastair Hales of University of Bristol and Prof Greg Offer of Imperial College London will partner with Thermal Hazard Technology (THT) to develop a common testing framework to improve the parameterisation of battery models. The testing framework will provide improved tools and methods for a more efficient product development processes and learnings will be incorporated into THT’s market-leading thermal control apparatus used for battery testing. The Fellowship will mark a transfer of knowledge from the Multi-scale Modelling project and the TOPBAT industry sprint to a commercial product of a new UK-based industry partner.